360° Discontinuous Fiber Composites (DFC)

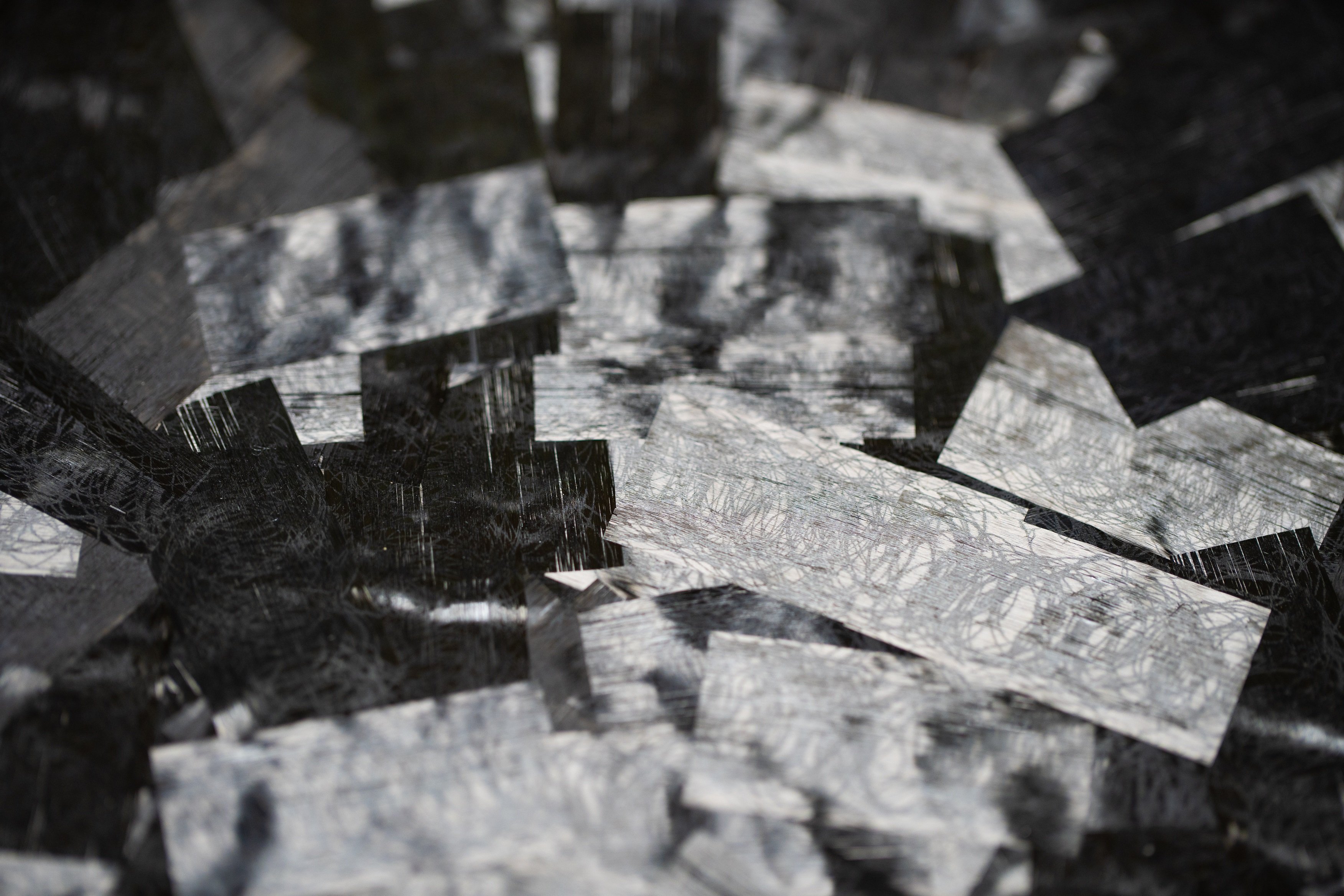

TeXtreme 360° belongs to a new class of composite materials called tape-based Discontinuous Fiber Composites (DFCs) which combine in-plane isotropy, high strength and stiffness and enhanced manufacturability. TeXtreme® 360° is made from randomly distributed ultra-thin TeXtreme® Spread Tow Tapes, which are partially impregnated with an epoxy matrix.

TeXtreme® 360° can reach high stiffness, strength and fatigue performance which makes it a good alternative to metal alloys or even continuous fiber composites. TeXtreme® 360° differs from the traditional Sheet Molding Compounds (SMCs) in terms of performance, design flexibility and processing. In-plane isotropy can be achieved for thin laminates with a cured plate thickness of about 0.5mm.

TeXtreme® 360° has been designed to be used in press forming/press molding processes at intermediate pressure levels (below 20 bars). Preforms of TeXtreme® 360° are typically shaped prior to consolidation and curing. TeXtreme® 360° can also be co-cured to other prepreg materials.

TeXtreme® 360° can also be supplied as non-impregnated using TeXtreme® dry Spread-Tow tapes.

Frequently Asked Questions

Here's a list of commonly asked questions. This page is continuously updated, so please revisit for new information or feel free to reach out to us directly if you have additional inquiries.

.jpg)